Is this what you need?

- Do you design your own products or manufacturing processes?

- Are your products optimized in terms of material use, manufacturing costs or performance?

- Have you got reliability issues, field service complaints or high warranty costs?

- Do your products need to comply with Industry Standards such as ASME or API?

All your needs in NZ CAD Works

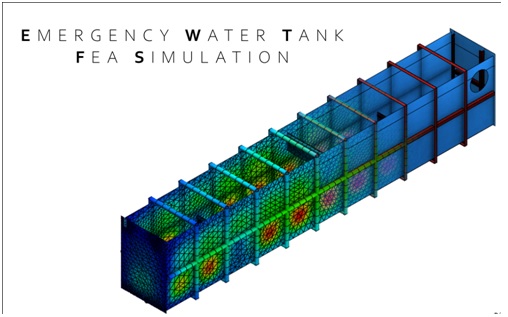

We can display and reenact your items or cycles utilizing FEA to all the more likely figure out their mechanical and warm way of behaving, Advance your plans without the need of costly preliminaries and tests with our FEA administrations.

Our FEA counseling engineers have immediate and approved insight in definite pressure examination, direct elements (typical modes, sin clear, PSD or seismic examination), from heat exchangers to NQA-1 atomic and in like manner, from development to transportation, nonlinear contact examination for muddled gatherings and plastic string configuration, high-power transmissions and stuff congregations, seaward oil fix winches, top drives, and numerous different fields.

We have likewise been dynamic in the environmentally friendly power field with complete mechanical pressure and dynamic examination of wind turbine frameworks, sunlight based chargers and photovoltaic frameworks. We really focus on FEA examination and our experience has been procured the most difficult way possible by having our models approved in test and in help for north of 20 years.

Static Analysis

- Plastic breakdown evaluation as indicated by ASME VIII, Programming interface 6 and PD-5500

- Direct and non-straight pressure investigation

- Multi-bodies multi-contact investigation

- Composite displaying and reenactment administrations

- Computer aided design and FEA network age administrations

Dynamic Analysis

Vibration FEA services

- Vibration FEA administrations

- Weakness appraisal as per ASME VIII, Programming interface 6 and PD-5500

- Symphonious and modular FEA examination

- Seismic investigation as per ASCE 7-02

- Recurrence reaction investigation

- Transient unique examination

Explicit dynamic FEA services

- Influence investigation, including subsea dropped object studies

- Crash investigation

- Metal shaping investigation

Fatigue analysis

- Exhaustion appraisal as indicated by ASME VIII, Programming interface 6 and PD-5500

- Warm stacking exhaustion appraisal

- Break engendering FEA

- Weld detail exhaustion examination

- Low and high cycle exhaustion

Thermal analysis

- Consistent state and transient warm examinations

- Radiation, convection and conduction warm investigation

- Plate and shell-and-cylinder heat exchanger execution evaluation

- Stage change warm administrations

Transient analysis

Transient or time-ward or time venturing investigation is led when the framework’s limit condition changes regarding time. Pretty much every framework changes with time, it is utilized to catch understanding into time-shifting stream highlights or peculiarities which would some way or another be hard to catch in actual testing.

For any transient reenactments, it is critical to choose suitable time step expected to catch the stream material science, too huge a period step will bring about lost detail and a period step which is too little will increment computational endeavors. The right actual model, time step size and client characterized capabilities (UDF) is proper to catch the material science with less approximations.

Why you should consider outsourcing finite element analysis with us ?

In today’s design process, FEA (Finite Element Analysis) serves as a vital analysis tool. In the last decade or so, it has become the go-to method when it comes to testing, interrogating, and perfecting design before the physical prototyping stage.

Recent advancements in computer technology have made FEA a lot more accessible to smaller manufacturing organizations and engineering firms. However, engineering managers still have to decide whether they should invest in in-house FEA resources, or reduce O&M costs and minimize risk by working with a third-party FEA consultant.

Now, developing FEA capability in-house is about much more than purchasing a special software. There is a myriad of additional costs associated with training, licensing, operation, hardware, validation and utilization, and staff compensation. The yearly costs of having in-house FEA capabilities can be much higher than the expense of outsourcing it to a third-party consultant for individual, short-term projects.

Considering this, here are some reasons why you should think about outsourcing FEA.

Training

Having cutting-edge hardware and the best software won’t get you anywhere until you have people who have the skills to get the best out of them. Getting familiar with the software’s nuances and developing FEA experience can have a huge effect of your simulations’ efficacy. It really is a form of art to define a proper simulation. High-res models take a long time to run but can deliver much more accurate results. Low resolution run fast, but that comes at the cost of decreased accuracy. Hitting the perfect balance requires a combination of experience, understanding, and knowledge. It requires effort and time to build capability and competency.

The last word

When you outsource projects to a licensed and experienced FEA consultancy firm, you don’t have to go through the hassles of purchasing software licensing, hiring a staff, and building capability and competency. Instead, you can invest the time and money into the other core aspects of your enterprise.